|

|

Forum Index : Electronics : Started Buck converter project

| Author | Message | ||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yup. Cheers, †Tony. |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I am glad someone is paying attention, I am suffering from information overload. The fast recovery diodes have arrived and will post results when available. Thank you very much. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Bigger cap, faster diode, and link the two grounds together should make a world of difference. Cheers, †Tony. |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

http://www.youtube.com/watch?v=B3dLzZZ5jKQ&feature=youtu.be 50 watt load video Greetings, I added the larger caps to the boot strap and the ringing is still there but only noticeable at lower RPMís. I am still using the 555 timer. I increased the duty cycle to 80% and inverted the output so the duty cycle at the input of the IR2117 is 20% high. I connect a 12 volt 50 watt light and spinning the PMA manually I was able to illuminate the 50 watt light with relative ease. Wow, a shorter duty cycle made all the different. The PMA was much easier to spin and even maintained momentum for a short period when I stopped spinning the PMA. Without the buck converter I was unable to illuminate the 50 watt load under manual operation. I am still using the bench power supply to power the ICís. Performance has definitely improved.

I still need away to control the duty cycle at different PMA RPMís and find away to power the ICís from the battery or PMA. Next step is to try charging the battery. It maybe time to start thinking about adding a micro controller. Thank you for all the suggestions. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I am still not sure why the 555 is ringing, but I suspect either power supply decoupling or grounding may be the problem. Two choices to replace the 555. You can use a microcontroller to generate the PWM waveform directly in software, or use a standard switching power supply control chip (of which there are many different types) to generate the PWM using standard analog control methods. A lot depends on your overall control strategy, and what the whole thing is expected to finally do. And whether you feel more comfortable writing software or designing it all in hardware. There are advantages and disadvantages either way. Cheers, †Tony. |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I was considering expanding the project using a micro controller. http://www.arduino.cc/ I have limited experience with C/C++, Basic.Net, and assembly code. Arduino is open source and low cost. I need to do some experimenting to determine a MPPT algorithm. A hard wire solution maybe to use a voltage control feedback circuit to control the duty cycle. I will start searching for a circuit. Comments are welcome. The next step is get the circuit working connected to 12 volt battery. I will post results when available. Thank you for all the help I have received. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Software is definitely much more flexible and easily changed, but I am not sure if the Arduino circuit boards can output high frequency PWM directly ? If not, you may need to look at using one of the analog output voltages from the Arduino to control PWM generated in a switching power supply control chip. This also has the advantage that initially you can control the PWM duty cycle from a potentiometer, much as you are already doing now. That splits the system into two definite halves. The Buck Regulator power control part, which you are well on the way to completing, and a separate Arduino "brain" to control the power electronics "muscle". Cheers, †Tony. |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi G Having experimented with some MPPT controllers, I would like to add a few comments to the excellent advice that you have been getting from Tony. Regarding a maximum power point tracker, as I see it, you have two basic options. One is to utilize a wind speed signal to adjust the apparent load on the turbine (ie its output voltage) so that you maintain a constant tip speed ratio (ratio between turbine speed and wind speed). This is easy to do with analogue control circuitry. The problem is in measuring truly representative incident wind speed, which should be measured directly in front of the turbine, and at least 2 diameters away. This is obviously difficult physically. The virtue of a TSR control scheme is that, once you have tuned it to the optimum ratio, you probably don't need to do anything more. Another approach that does not need a wind speed input is to measure and store the alternator output power (could be battery current) then change the alternator voltage by a small amount, pause for a short time, then compare the new output power with the previous one. If the power is greater, then make a further change in the same direction, but, if it is less, then make a change in the opposite direction. For the second type of scheme, a micro-controller is really the only practicable driver, and the beauty of using a controller is that its output is so readily changeable while you are experimenting. My favourite is the picaxe, because I don't find its software difficult to learn, but I have not tried any of the others. The square wave PWM output from a picaxe (or any other micro really) will do away with many of the problems that you have been experiencing with your analogue circuitry. The mark-space ratio (ie controlling the alternator voltage) is easy to manipulate with a PWMduty statement (picaxe), and the actual mark-space ratio in that statement can be a variable word (0 to 1024 bits - picaxe at 255 duty cycle = 4 kHz approx)). The variable word can be calculated from any combination of analogue input, look up table, etc. This may all sound quite foreign, but it is really straight-forward once you get into it. Have a look at the picaxe site and the tutorials, which, I am sure, probably have equivalents with arduino or maximite. On the matter of power to drive the gate/s of your N type Mosfet/s, I have recently taken the easy road and used two SPRO1L-05 5V to 5V DC-DC converters with their secondaries connected in series to get 10V. They are small, and cost around $10 each. The 10V output negative gets connected to the Mosfet source line, so that their voltage jumps up and down with the source voltage changes. Their 5V input come from the same supply that operates the micro. The micro PWM output drives the LED side of a 4N25 opto, the output of which drives a 4093 NAND schmidt chip operating off the 10V Mosfet gate drive rail. The NAND schmidt squares up the drive from the opto, and drives the Mosfet gates via a 47 Ohm resistor. The beauty of using (all 4 elements of) a driver chip such as the 4093 is that it quickly discharges the Mosfet gate capacitance to turn it off as well as quickly turning it on. I can recall an earlier thread on this forum of a simple but apparently effective MPPT using analogue circuitry and, while I can't recall the details, it might provide a stepping stone to progress your project. Certainly, some of the comments made then would be very relevant to your situation. I still think though that you should investigate using a micro-controller, as they do give you the flexibility to readily try different control strategies that would be very frustrating to attempt with analogue circuitry. Regards Don B |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Don has raised some very significant points about MPPT. There are two fundamentally different approaches to the MPPT problem. The feedback method looks at the battery charging current, and slowly "rocks" the PWM value back and forth noting what the charging current does. The average PWM value is then slowly steered in the direction that suggests highest battery charging current. While this algorithm works fine for solar MPPT systems, for wind machines in very gusty conditions it can leave a lot to be desired. It simply cannot respond fast enough to rapidly changing wind velocity. The feed forward method is very different. It only measures instantaneous wind speed with a cup anemometer. The instantaneous wind speed references a lookup table that directly sets the PWM value. This system is very fast to respond, and cannot become unstable or confused by rapid wind speed changes. The disadvantage is, you have to do a lot of testing to determine what the PWM duty cycle should be at various wind speeds, to correctly program the lookup table. So the choice is feedback, or feed forward correction to set the PWM duty cycle. Just one more design choice to make. Cheers, †Tony. |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, what is the high end limit of Vin from the PMA for your project? Because I constructed my PMA stators with inputs and outputs it can be configured so all the stators are in parallel for a low voltage with high current output or the stators can be configured in series for a very high voltage output, over 200 volts, and lower current. So far I have only tried the stators connected in parallel using a resistive load with the buck switching fixed at 10 kHz with 50% and a 20% duty cycle. It worked best with the shorter duty cycle under manual operation. I am still trying to understand what is required for battery charging and what will be the upper limits for Vin from the PMA. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The voltage step down will be exactly proportional to the on time compared to the total time of your PWM. For example: If PWM 50% on 50% off, output voltage will be half the input voltage. If PWM is 33% on 66% off, output voltage will be one third the input voltage. If PWM 10% on 90% off, output voltage will be one tenth the input voltage. Only practical upper limit to input voltage will be the voltage rating of the MOSFET and catch diode. Both of these also need to be rated for the full output current. A practical system might step say 96 volts 1 Amp down to 12 volts 8 Amps. Absolute minimum safe ratings for both MOSFET and diode might be 100 volts 10 amps for both. Cheers, †Tony. |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, The circuit is working with a resistive load. 1. The mosfet source is connect to the high side of the load. The mosfet is a IRF510. 2. A IR2117 with bootstrap is being used and is referenced to Vs so the bootstrap capacitor voltage can be charged high enough to turn on the mosfet. 3. A 555 timer is used to control the IR2117 @ 10kHz with a Vcc of 12 volts. 4. A permanent magnet alternator is used to supply Vin and can range from 0 to over 200 volts depending on the permanent magnet alternators RPM. 5. A bench power supply is used to supply power to the ICís. This will be changed later. The problem is : When the resistive load is replace with a 12 volt battery the circuit does not work. I do not understand why the circuit will work for a resistive load and not with a 12 battery as a load. Any suggestion will be greatly appreciated. http://www.ti.com/lit/ml/slup169/slup169.pdf on page, 26 Figure 29 maybe the solution. What value should Dz be? just because your a GURU or forum administer does not mean your always correct :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

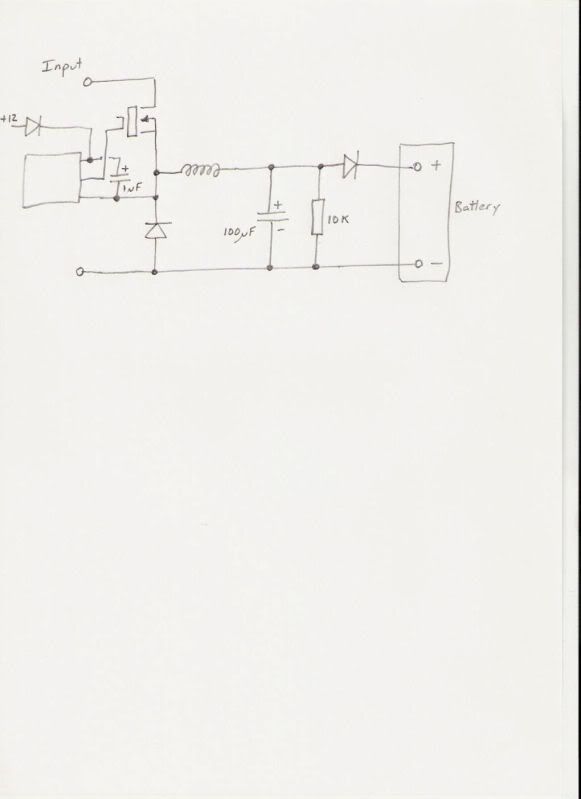

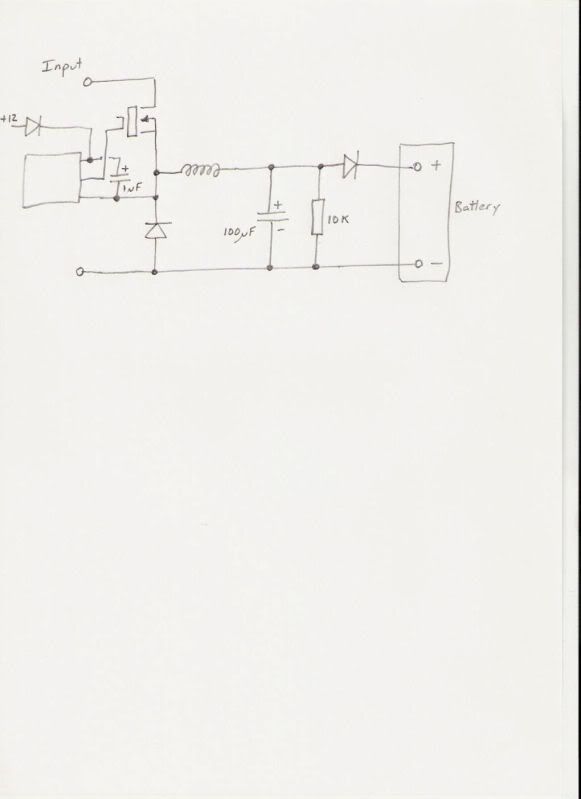

I was expecting this, but was not completely certain it would happen. The bootstrap capacitor charges through the diode, but it can only do that when the source of the MOSFET is pulled right down to ground potential. With a resistive load, the load pulls the source down to ground whenever the MOSFET turns off. Now that the load is a battery, the source of the MOSFET sits up at at battery voltage when the MOSFET is off, and the bootstrap capacitor has no means of charging. However, once the buck regulator DOES start, the back EMF from the buck regulator choke will be more than sufficient to slam the MOSFET source hard right down to ground. So it should run fine with a battery, but there is no way it can start up with a battery, at least not the way it now is. It needs some help to kick start it, but once running it will work fine. There are several ways to fix this, but the easiest is to place a resistor and capacitor to ground after the buck regulator choke, and fit a diode between the buck regulator choke and the battery. The idea is, the capacitor at the choke output will be fully discharged when power is first applied, this effectively grounds the MOSFET source, when the MOSFET is off, allowing the bootstrap capacitor to charge. Once charged, the circuit will continue to run. The resistor just discharges this capacitor, prior to any restart. The capacitor does not need to be very large, just a lot larger than the bootstrap capacitor. And the resistor can be fairly high value, just enough to discharge the capacitor over a few seconds. Something like this should kick start it into action with a battery connected:

Cheers, †Tony. |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I am still trying to understand what is important or the needed condition to turn the mosfet on. Is it just 10 volts at the gate above the voltage at the Source and the voltage level at the Drain is not considered? So 10 volts at the Source requires 20 volts at the gate or is there more to it?? I have read so many different posts I am really confused. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

When the MOSFET is off (open circuit) the source must be arranged to always return right down to ground potential. That is a fundamental requirement of this type of circuit. It will do that naturally with just a pure resistive load that has one side grounded. With the MOSFET source sitting at ground potential, the 1uF bootstrap capacitor is then able to charge up via the +12v supply and the diode. The stored charge on the bootstrap capacitor will then power the isolated output half of the gate driver chip. The isolated gate driver chip is then able to place a positive gate voltage onto the MOSFET with respect to the source by taking power from the bootstrap capacitor. As the MOSFET turns on, the source voltage rapidly rises up to maybe a couple of hundred volts. It carries the bootstrap capacitor along with it, and the gate voltage is maintained at a higher positive voltage relative to the source voltage, powered from the bootstrap capacitor. Eventually the bootstrap capacitor would discharge, but as long as the "on" time of the MOSFET is not excessively long, the bootstrap capacitor can again recharge after the MOSFET turns off, and the source drops back down to ground potential. The bootstap capacitor charges while the MOSFET is "off". And it provides a fully floating gate drive power source when the MOSFET is "on". Cheers, †Tony. |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

If you think about an N channel mosfet on its own, it is normally connected so that the drain is more positive than the source It should also be noted that a mosfet has an inherent diode between the source and drain that will conduct if the source is made more positive than the drain (you can measure this with a diode tester). A mosfet will not begin to conduct between drain and source until the gate has a certain value of positive voltage with respect to the source. When used for switching, you want the mosfet to conduct fully (ie with minimum resistance between drain and source), and, to do that, you need to bring the gate to its full on conducting voltage (between 5 and 15 V depending on the mosfet) as quickly as possible. The gate is essentially a capacitor, consequently, some charging current does flow while it is turning on. When you want to turn a switching mosfet off, you need to discharge the gate relative to the source as quickly as possible. Again, a discharge current will flow. Note that it is possible to charge and discharge the gate too quickly, causing damage to the mosfet. This is why there should always be a low value resistance (10 to 100 Ohms) in series with the gate. Because quickly discharging the gate is as important as quickly charging the gate, the gate swtching circuit should switch hard down to the source voltage when turning off, rather than merely disconnecting the gate on voltage and letting the charge dissipate somehow. Note that the gate needs to be at either maximum gate voltage or at zero volts relative to the source. not the zero volts line. When you use an N channel mosfet on the high side of the load, the source voltage relative to ground shifts between the drain voltage level when on, and varies between one diode drop below ground and the high side load voltage level when off. The gate drive voltage source therefore needs to have its negative side connected to the mosfet source rather than ground, and it is difficult to derive a gate drive voltage directly from the input voltage. Having experimented with diode pump circuits, which certainly can be made to work, I now think it simpler to use the small, cheap, DC DC converters like the SPRO series to obtain an isolated gate drive voltage. These are isolated to 200V, and have ample capacity to drive several mosfets in parallel, if needed. I can provide a circuit for doing this, if you wish. One final comment on mosfets. Like most things in life, they are a compromise. The ones with the lowest on resistance usually also have the lowest maximum voltage rating(40 to 50 Volts). As you get higher voltage rated ones, the on resistance, and hence the losses and heating, also increase. Of course, as you raise the operating voltage, the current that you need to transmit a certain power level decreases. It becomes a bit of a balancing act though to select the optimum operating voltage level. Regards Don B |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, I am not familiar with the parts your describing and a schematic would be greatly appreciated, Thank you just because your a GURU or forum administer does not mean your always correct :) |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

If the upload has worked OK, then this circuit shows one way of driving your Mosfet even continuously on if needed. I have had a quick look at the IR2110 specs, and note that it can do much the same job as my circuit, and probably more elegantly. It can not turn the mosfet on continuously though unless it is provided with a separate floating power supply. While I use the SPRO1L-05 DC-DC converters for this, Figure 16 of the IR2110 application notes uses a 555 oscillator and diode pump circuit to provide the (continuous) floating supply. I do not know what mosfet you are using, but 10V is usually sufficient to turn most of them fully on. Most will also tolerate a higher gate voltage (say 15 V), but will not turn on any harder. An excessively high gate voltage just needlessly increases the gate charging and discharging current, and actually slows the turn off time. Note also the 15V Zener connected between the gate and source. This will hopefully protect your mosfet against any spikes induced into the gate circuitry, which could otherwise destroy it. The following comments may help in your experiments: The switching of switchmode circuits generates almost square waves. These have some very high frequency components, which can interfere with circuit operation. In particular, where things are physically connected to the 0 Volt line can be critical, and the connection between the electronic circuit grounds and the power circuit ground should be at one point only, otherwise small voltage drops from the flow of power circuit current will be imposed into the electronic circuits, and may cause some mischief. Long wires should be avoided, and also try to segregate the electronic and power circuit wiring, as otherwise capacitive coupling between the two can cause problems. You appear to be using an air cored inductor. While there is nothing inherently wrong with this, the inductor will generate a wide spread magnetic field that can induce currents in the rest of your wiring, and also radiate interference into other electronics. Far better to wind your inductor on a (decent sized) ferrite torroid, and then the field will be almost fully contained. Make sure that the electrolytic capacitors that you use across the input and the load are of a decent size, suitably voltage rated, and of the low ESR (equivalent series resistance) type. I also tend to fit a 0.1 uF capacitor in parallel with them to bypass higher frequencies. When you monitor the source voltage relative to ground on your oscilloscope, you will see the source voltage rise to just below the drain voltage when the mosfet turns on. When it turns off, the source voltage will actually go slightly negative relative to the 0 V line, and will either stay there for the full off time, or will commence to rise to the high side load voltage as the energy stored in the inductor as a magnetic field fully dissipates. This should not be confused with ringing, which will involve overshoots, and some oscillations. If you can get hold of a book entitled Switching Power Supply Design by Abraham L Pressman (McGraw Hill), it will explain in much more detail the many factors involved in switchmode design and operation. Regards Note that the floating supply shown as 5 V on the diagram should read 10 V. Don B |

||||

| govertical Guru Joined: 11/12/2008 Location: United StatesPosts: 383 |

Hi, Wow, this is great. I found a possible solution from a manufactures application notes, plus the two methods suggested here, hopefully I will be able to be get one of them to work. I think I have all the parts to try all three. I will post results when available. Thank you, this circuit is very important for the system to work well. I was checking old test data and the system without the circuit required a 30 MPH to output 4 amps @ 12 volts, with the circuit, driving a resistive, the PMA can output 4 amps under manual rotation. Thanks again. just because your a GURU or forum administer does not mean your always correct :) |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

One further comment on the DC-DC converters. I use the SPRO1L-05 because they are locally available. If you look at the SPRO data sheet (from Mean Well??), they are available in a range of input and output voltages and a different model might suit your purposes better. All you then need to do is track down a supplier. Regards Don B |

||||